Understanding the Roof Replacement Process and Costs

Outline:

1) What roof replacement involves and how the process unfolds

2) Choosing shingles: materials, performance, and climate fit

3) Cost factors: line-item breakdown, ranges, and savings

4) Installation details: sequence, code basics, and quality checks

5) Maintenance, timing, and a practical conclusion

From Tear-Off to Final Inspection: How Roof Replacement Actually Works

Roof replacement is less about swapping shingles and more about rebuilding a weather shell that governs temperature, moisture, and durability. Think of it as a system: deck, underlayments, flashing, shingles, and ventilation must act in concert. The process starts with a thorough inspection of the existing roof and attic. A pro checks for deck softness, failed flashing, inadequate ventilation, and moisture staining on rafters or insulation. From there, scope is set: full tear-off versus overlay (where allowed), deck repairs, and any code updates such as ice-barrier in cold regions. Permits are secured, materials are staged, and site protection begins—landscaping is covered, tarps are laid, and gutters are safeguarded.

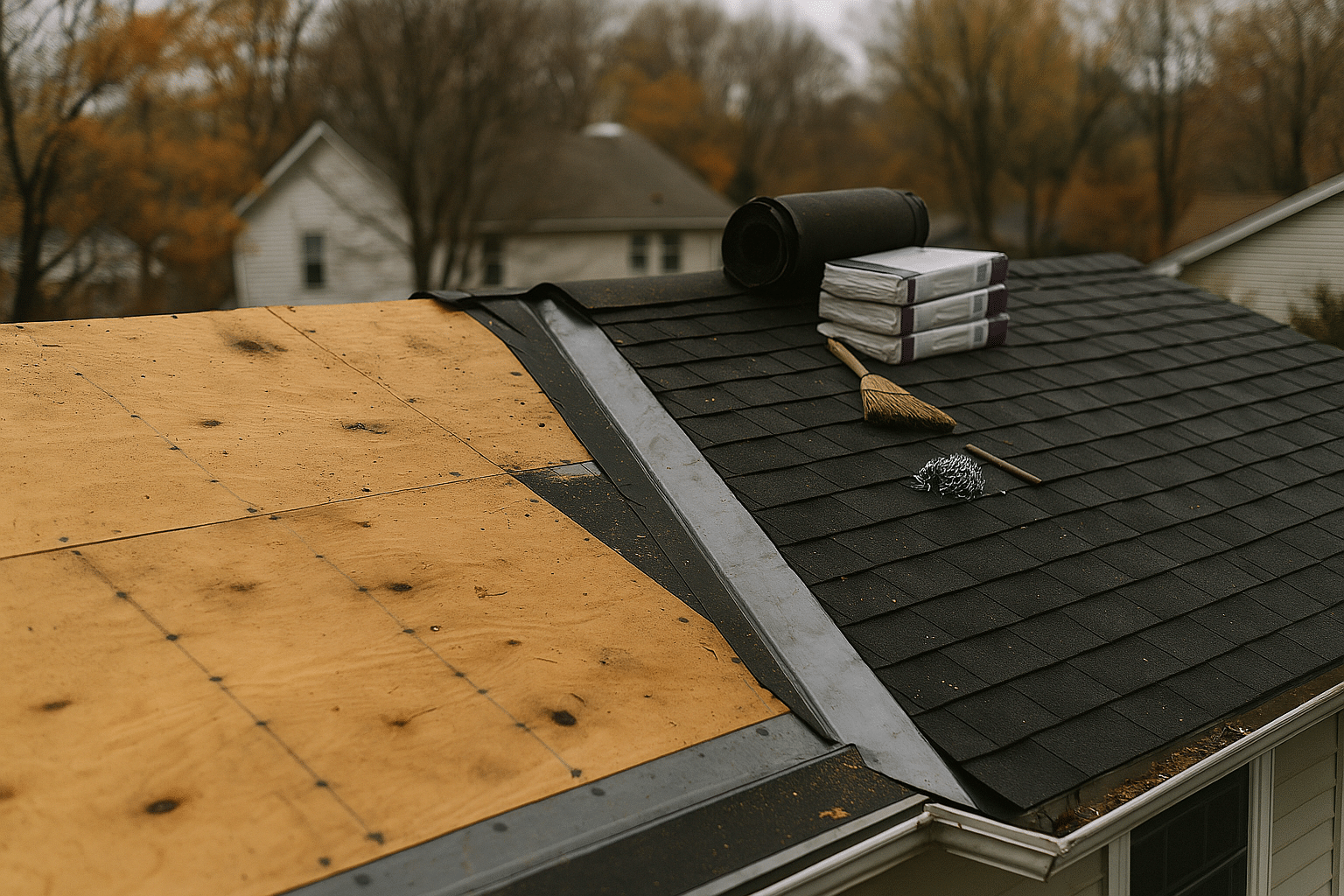

Tear-off reveals the truth. Crews remove old shingles and underlayment, prying up flashing around chimneys, skylights, and walls. Exposed sheathing is inspected; damaged sections are replaced, fasteners are retightened, and high spots are planed. With a sound base, water defenses go in. Along eaves in cold climates, a self-sealing membrane helps guard against ice dams. Synthetic or felt underlayment covers the field, drip edge trims the roof perimeter, and valleys receive metal or reinforced membranes depending on design choice. Proper sequencing matters: at eaves, drip edge typically sits beneath underlayment; along rakes, it often laps over, channeling runoff correctly.

Next comes shingle layout and fastening. Starter strips lock the first course, and field shingles follow with manufacturer-specified exposure and nail placement. In higher wind zones, six nails per shingle and sealed edges add uplift resistance. Flashing is rebuilt meticulously—step flashing at sidewalls, saddle flashing behind chimneys, and boots around vents—then counterflashing is integrated into masonry to shed water. Ventilation is balanced with intake at the eaves and exhaust at the ridge, helping regulate attic humidity and temperature, which protects the roof and improves indoor comfort. Finally, ridges are capped, debris is magnet-swept for nails, and a final walkthrough checks details like straight coursing, sealed penetrations, and clean valleys. For many average homes, a one- to three-day window is typical, but complex rooflines, steep slopes, or weather delays can extend the schedule. The goal is a system that looks sharp on day one and performs reliably for years, not just a quick cosmetic fix.

Shingle Choices Compared: Lifespan, Climate Fit, and Curb Appeal

Picking shingles is part science, part style. Materials differ in weight, longevity, wind and hail performance, fire rating, and how they handle heat or moisture. Asphalt remains widely used because it balances cost, color variety, and straightforward installation. Traditional three-tab shingles are lightweight and budget-friendly, often lasting about 15–20 years in moderate climates, while thicker laminated (architectural) varieties commonly reach 25–35 years thanks to heavier mats and layered construction. In hot, sunny regions, look for higher reflectance pigments that reduce heat absorption; in humid areas prone to staining, algae-resistant granules help maintain appearance.

Metal shingles offer notable longevity—often 40–60 years—plus low weight (frequently under 1.5 lb per square foot). Their interlocking profiles can deliver strong wind resistance and quick water shedding. Wood shingles and shakes supply a warm, textured look and can perform well in certain dry climates when maintained, often achieving 20–30 years; however, they require diligent care against moisture and wildfire risk where applicable. Composite and polymer shingles emulate slate or wood with lighter weight and consistent factory quality, frequently spanning 30–50 years. Natural slate is the heavyweight classic, with exceptional durability that can exceed 75–100 years, but its mass (commonly 8–12 lb per square foot) demands structural verification.

Quick comparisons to guide shortlisting:

– Lifespan: asphalt (15–35 yrs), wood (20–30 yrs), metal (40–60 yrs), composite (30–50 yrs), slate (75–100+ yrs)

– Weight (approx.): metal (<1.5 lb/sf), asphalt (2–3 lb/sf), wood (3.5–5 lb/sf), composite (2–4 lb/sf), slate (8–12 lb/sf)

- Climate notes: high heat favors reflective surfaces; freeze–thaw cycles reward robust underlayments and careful flashing; coastal wind calls for higher wind ratings and additional fasteners

- Sustainability: metal and some composites are recyclable; cool-color shingles can cut cooling demand; long-lived materials reduce replacement waste over time

Aesthetics still matter. Architectural profiles add shadow lines that elevate curb appeal and can help mask minor deck irregularities. Darker tones visually compact tall homes; lighter hues can diminish heat gain in sunny regions. Granule blend complexity can hide dirt and pollen between washes of rain. Whatever you shortlist, check local building code requirements, neighborhood guidelines, and roof structure capacity. Matching material to climate, budget, and architecture delivers a roof that works as good shelter and a quiet design upgrade from the street.

What It Really Costs: Line-Item Budgeting and Smart Savings

Roof pricing comes from three buckets: materials, labor, and project conditions. Costs vary by region, roof complexity, and season, so consider the following ranges as planning anchors. For asphalt shingles, many homeowners see installed prices around $4.50–$8.50 per square foot, or roughly $450–$850 per 100-square-foot “square.” Laminated profiles trend higher within that band. Wood shingle or shake systems often run $7–$12 per square foot installed, while metal shingles frequently land near $8–$14 per square foot depending on profile and accessories. Composite products commonly range $8–$13 per square foot. Natural slate can span $15–$30 per square foot or more due to material mass, specialized labor, and reinforced flashing details.

Beyond the field shingles, expect additional line items:

– Tear-off and disposal: about $1.00–$2.00 per square foot, influenced by layers removed and haul distance

– Underlayments: approximately $0.30–$0.75 per square foot for synthetic or felt; ice-barrier membranes cost more in cold zones

– Flashing and metals: commonly $400–$1,200 depending on number of walls, chimneys, skylights, and valleys

– Ventilation: $300–$900 for components such as ridge vents, baffles, or upgraded intake

– Deck repairs: $2.00–$6.00 per square foot replaced if rot, delamination, or over-spaced boards are found

– Permits and inspections: $100–$500, though local fees vary

Conditions that influence labor pricing:

– Steep slope: pitches above 6:12 can add 10–25% or more to labor for safety and staging

– Height and access: multi-story homes, tight lot lines, and limited driveway access increase setup time

– Roof shape: hips, dormers, multiple valleys, and skylights introduce detail work and flashing complexity

– Weather windows: extreme heat or cold slow production and impact adhesive sealing performance

To stretch value, align your project with slower local seasons, bundle needed upgrades (such as ventilation or gutter work) to reduce multiple mobilizations, and request detailed written scopes that specify materials, nail counts, underlayment types, and flashing approaches. Compare warranties thoughtfully—some cover manufacturing defects while separate workmanship warranties cover installation quality. Insurance may participate if a covered peril caused damage; keep documentation, dates, and photos organized. Typical resale studies show that a new, well-installed roof often recoups a meaningful share of its cost—frequently in the mid-range return category—while providing peace of mind that’s hard to price. Transparent line items and a clear scope transform estimates from a mystery into a plan you can evaluate confidently.

Installation Details You’ll Care About: Sequence, Craft, and Code Basics

Once materials arrive and the old roof is off, the sequence and craft determine how well the new system performs. A solid deck is non-negotiable: replace delaminated plywood, tighten fasteners into rafters or trusses, and correct uneven surfaces that telegraph through shingles. Along eaves in cold climates, an ice-barrier membrane extends from the edge to at least 24 inches inside the warm wall line, helping block backed-up meltwater. Underlayment covers the remainder, with adequate overlaps and cap fasteners flush but not tearing the sheet. Drip edge placement is purposeful: at eaves it typically goes beneath underlayment to direct water into the gutter; at rakes it often sits over underlayment to shield edges from wind-driven rain.

Valleys deserve special attention. Open metal valleys shed water quickly and are resilient in debris-prone areas; closed-cut or woven valleys create a continuous shingle surface with distinct aesthetics. Around sidewalls, step flashing is installed piece by piece with each shingle course, and then counterflashing or siding layers overlap to shed water. Penetrations such as vents and stacks get boots with sealed flanges and fasteners outside the water path. Starter strips along eaves prevent blow-offs; field shingles follow with exposure set to the layout lines. In many zones, four nails per shingle is standard, moving to six in higher wind ratings. Nails should be driven flush into the nailing strip—not overdriven or angled—to avoid cut-through or raised tabs.

Ventilation ties the roof system to attic health. Aim for balanced intake and exhaust, with many codes referencing around 1:300 net free vent area (NFA) when a proper vapor retarder is present, and 1:150 without, split roughly half intake and half exhaust. Continuous soffit vents feed a ridge vent so air moves uniformly; where ridge vents aren’t possible, box or gable vents may be used according to design and code. Weather matters too: shingle sealant strips bond best in moderate temperatures, and very cold conditions may require hand-sealing. Conversely, high heat can scuff granules; moving bundles gently reduces blemishes.

Quality checks and red flags:

– Straight, parallel courses consistently spaced across planes and into valleys

– Proper nail placement and count per shingle, verified at sample locations

– Clean terminations at walls with visible step flashing, not face-sealed caulk alone

– Ridge vent cut centered and continuous, with end plugs and appropriate cap coverage

– Granule runoff confined to initial weathering, not heavy accumulations indicating abrasion

Safety underpins everything: fall protection, ladder tie-offs, and tidy staging reduce accidents and keep the job moving. When sequencing is correct and details are crisp, the roof not only looks right—it breathes, drains, and endures as a unified system.

Maintenance, Timing Your Replacement, and a Homeowner-Focused Conclusion

The quiet secret of a long-lived roof is routine, low-effort care. Seasonal checkups—one in spring and one in fall—help you spot issues early. From the ground, scan for missing tabs, cupping, or uplifted edges; from inside, look for attic staining, damp insulation, or musty odors after heavy weather. Keep gutters clean so water doesn’t back up at the eaves, trim branches that scrape shingles, and sweep off twigs or pine needles that trap moisture. In shaded areas, treat moss and algae with products formulated for roofing, and avoid pressure washing that can strip protective granules. Around chimneys and skylights, watch for cracked sealant, displaced counterflashing, or rust at metal transitions.

Knowing when to repair versus replace saves money and stress. Isolated, accessible damage can often be patched effectively, especially on younger roofs. Consider full replacement when:

– More than roughly a quarter of the surface shows curling, cracking, or widespread granule loss

– Multiple leaks trace back to aged, brittle shingles or failed flashing across several areas

– The roof is nearing the end of its expected service life for its material and climate

– Decking feels spongy or fasteners are pulling through due to moisture history

Plan upgrades with foresight. If you’re considering solar, coordinating the array install with a fresh roof prevents future tear-off around mounts. Upgrading intake and exhaust ventilation during replacement helps stabilize attic temperatures, lowering the risk of ice dams and reducing cooling load in hot months. Opt for underlayments and membranes suitable for your climate, and ask for written workmanship and product warranties so responsibilities are clear. Keep a project folder with material lists, color selections, delivery dates, and photographs; this archive aids warranty claims and future maintenance.

Conclusion for homeowners: A roof is more than a cap—it’s your home’s first defense against water and weather, and a steady contributor to comfort and value. By understanding shingles, installation sequence, and the true cost drivers, you can choose confidently and set realistic expectations for schedule and outcome. Obtain detailed, apples-to-apples bids, verify licensing and insurance, and prioritize crews that explain their flashing and ventilation approach in plain language. With thoughtful planning and a focus on system quality, your replacement becomes a measured investment that pays you back in durability, efficiency, and quiet confidence every time the forecast turns stormy.