Understanding HVAC Installation and Repair Processes

Outline

– HVAC fundamentals: components, heat transfer, and efficiency metrics

– Pre-installation planning: sizing, duct strategy, site conditions, and permitting

– Installation and commissioning: sequence, tools, measurements, and documentation

– Maintenance and repair diagnostics: routines, instrumentation, and common fixes

– Repair vs. replace and conclusion: budgeting, timing, sustainability, and practical next steps

HVAC 101: How Systems Move Heat and Manage Comfort

At its core, an HVAC system is a heat mover and air manager. Cooling systems absorb heat indoors and reject it outdoors; heating systems add heat through combustion, electric resistance, or by reversing the refrigeration cycle. A typical split cooling setup includes an outdoor unit that rejects heat, an indoor coil that absorbs heat, a blower that distributes air, and a network of ducts that deliver conditioned air to rooms. Heat pumps look similar, but a reversing valve enables them to transfer heat in either direction, offering efficient heating in moderate climates.

Comfort is not only about temperature; it is the balance of sensible and latent heat. Proper airflow enables the coil to dehumidify effectively in summer, while adequate heat output maintains stable room temperatures in winter. Key efficiency metrics help compare options: SEER2 and EER describe cooling efficiency, HSPF2 and COP describe heat pump heating efficiency, and AFUE describes combustion furnace efficiency. A higher number generally indicates less energy use for the same comfort, but climate, utility rates, and load profiles determine what pays back in real life. Variable-speed blowers and modulating compressors can smooth temperature swings and reduce noise while maintaining humidity more consistently than single-stage equipment.

System performance is a chain; the weakest link sets the limit. Duct design affects static pressure, and high static pressure can slash airflow and reduce efficiency even if the equipment is highly rated. Leaky or undersized ducts, clogged filters, or obstructed returns often explain rooms that run hot or cold. Building envelope improvements—air sealing, insulation, and window shading—lower the cooling and heating load, making right-sized equipment feasible. Studies have reported that sealing ducts in older homes can cut HVAC energy use by double-digit percentages, with actual savings depending on leakage levels and operating hours.

In short, HVAC is a system that turns physics into comfort. When components are matched, ducts are designed for the needed airflow, and controls are calibrated, the system delivers steady temperatures and healthier indoor air—without inflated energy bills. When they are not, even new equipment can underperform. The rest of this guide shows how planning, installation, and maintenance keep those links strong.

– Components to know: outdoor unit, indoor coil, blower, filter, thermostat, and ducts

– Efficiency metrics to compare: SEER2/EER (cooling), HSPF2/COP (heat pump heating), AFUE (combustion)

– Comfort factors: temperature, humidity, airflow, noise, and air quality

Planning and Sizing: The Foundation of a Good Install

Before a single fastener turns, planning sets the trajectory of performance and cost. Sizing should be based on an industry-standard load calculation that accounts for square footage, insulation, air leakage, window area, solar exposure, and occupancy. Oversized systems tend to short-cycle, leading to poor humidity control, temperature swings, and premature wear. Undersized systems may run continuously on extreme days and still fall short. Accurate sizing targets the sweet spot: long, efficient run times without struggling to meet set point.

Duct strategy sits alongside sizing. Supply and return ducts must deliver design airflow to each room, typically planned in cubic feet per minute based on room load. Bends, reducers, and transitions should be gentle to limit turbulence, and static pressure targets need to align with the blower’s capability. Returns must be plentiful, with clear paths back to the air handler to prevent pressure imbalances that can draw unfiltered air from attics or crawl spaces. Thoughtful zoning can help, but it should be supported with bypass-free design and attention to minimum airflow requirements so equipment is never starved for air.

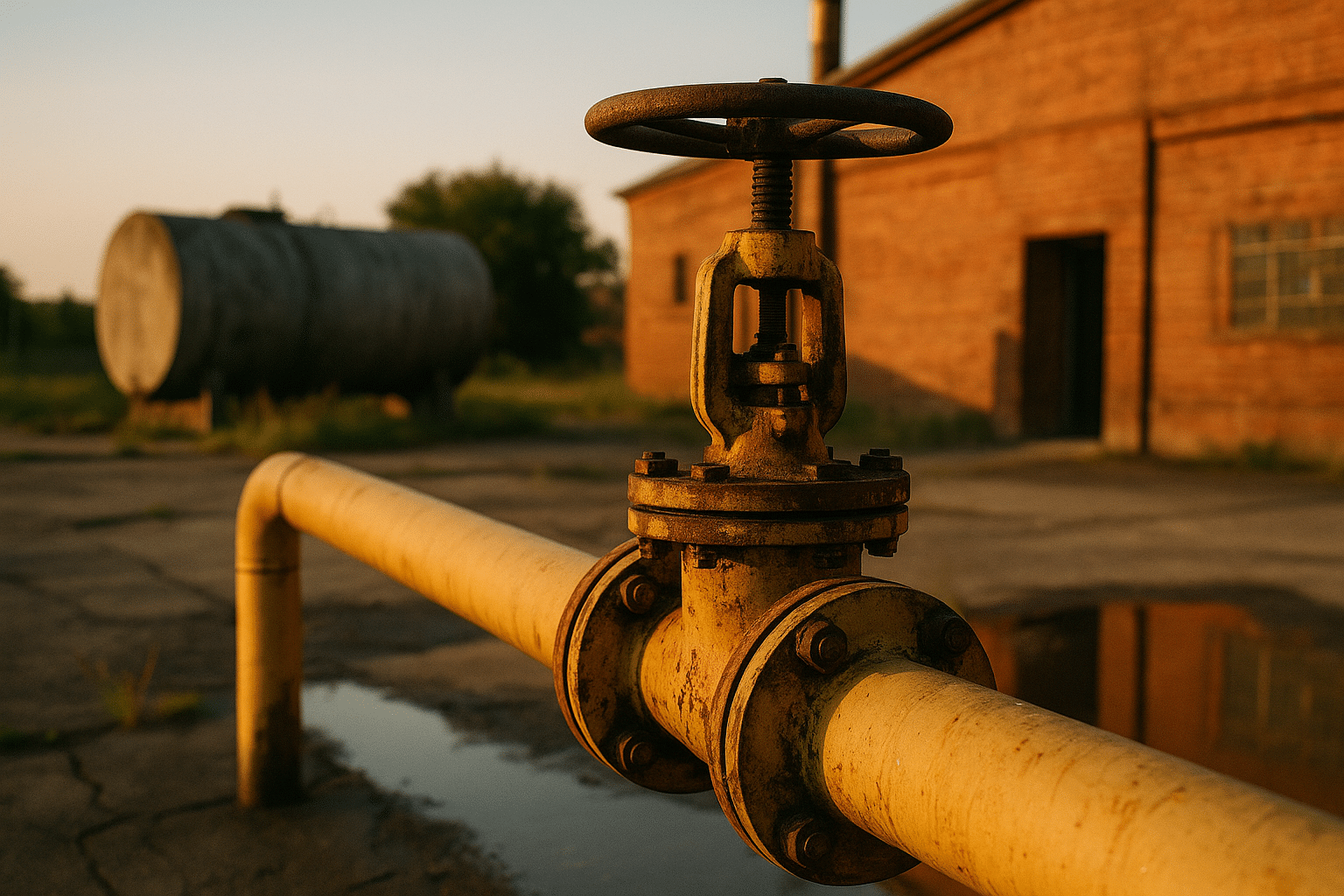

Site conditions matter as well. Outdoor units need clearance from walls and shrubs for airflow and service access. The line set path should be short, protected, and sized to manufacturer specifications, with insulation rated for the refrigerant’s operating temperatures. Condensate drainage requires a proper trap and slope; in humid climates a secondary safety switch can prevent water damage. Electrical service must match equipment demands, including breaker sizing, dedicated circuits, and grounding. Permits and inspections protect safety and ensure compliance with local codes, especially for combustion appliances and refrigerants.

Planning is also the time to consider comfort and air quality goals. If humidity has been a persistent problem, specifying a coil and airflow setup that supports dehumidification, or exploring dedicated ventilation with filtration, can pay dividends. Envelope upgrades may allow a smaller system; investing in air sealing before installation can reduce required capacity and improve comfort in every room. Documentation is your ally: request the load calculation summary, duct sizing notes, and equipment selection data.

– Pre-install checklist: load calculation, duct layout, electrical capacity, drain routing, permits

– Red flags: “rule-of-thumb” sizing, missing return paths, outdoor unit crammed into a corner

– Good-to-have details: vibration isolation, service clearances, and sun/shade considerations

Installation and Commissioning: Step-by-Step to Reliable Operation

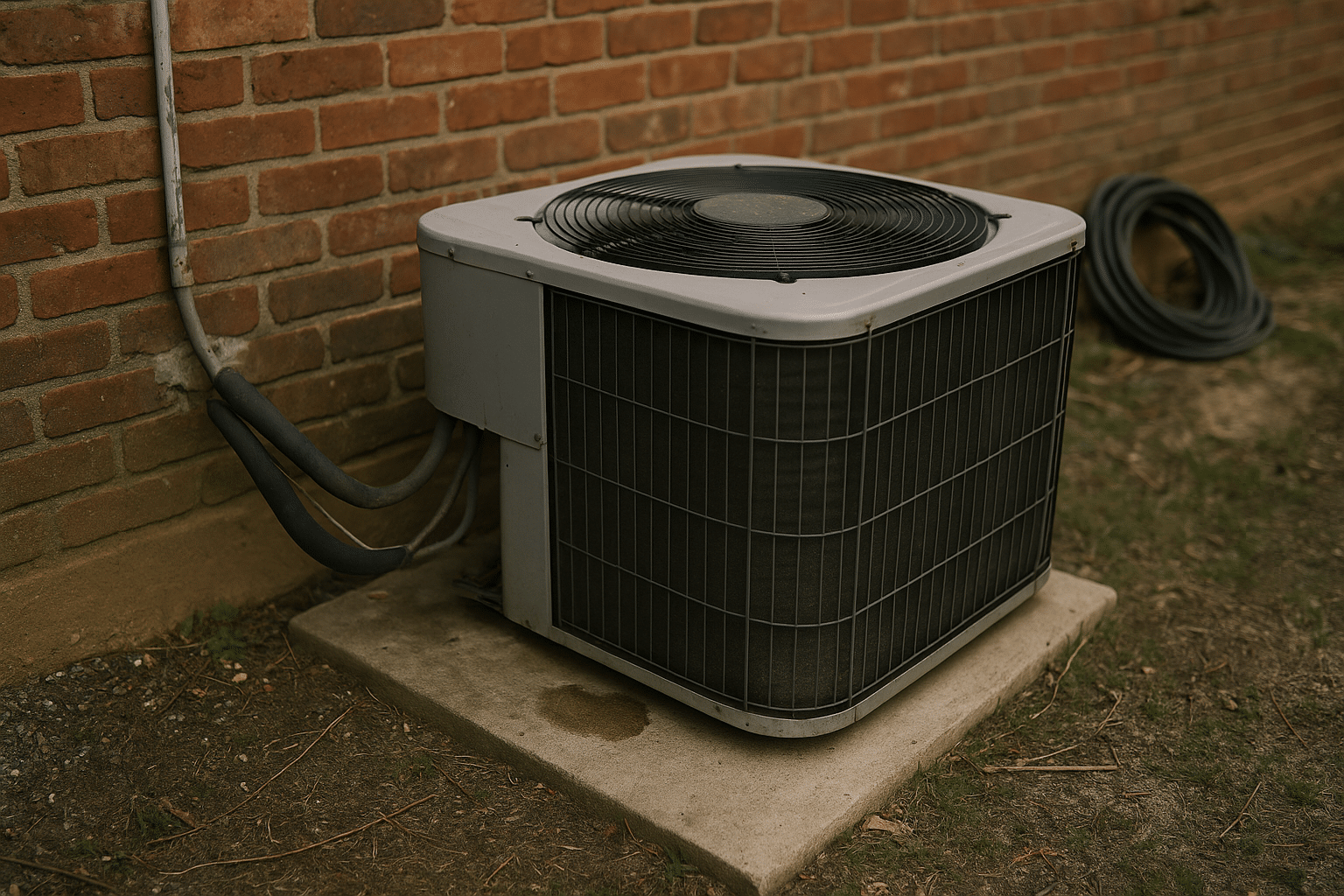

A careful installation follows a predictable sequence that safeguards performance. The outdoor unit is set level on a stable pad, with clearance for airflow and winter service. The indoor air handler or furnace is positioned to allow filter changes, coil access, and drain routing. Line sets are measured, cut, and routed with large, smooth bends to prevent oil traps; when brazing copper, a nitrogen purge helps avoid oxidation inside the tubing. After connections, a pressure test with dry nitrogen (commonly within a range specified by the manufacturer) verifies system tightness. Only when the system holds pressure without decay is it ready for evacuation.

Evacuation removes air and moisture so refrigerant can do its job efficiently. Technicians use a vacuum pump and a micron gauge to pull the system down to a deep vacuum—often near 500 microns—and then isolate and observe for a stable rise. A quick rebound suggests trapped moisture or a small leak, while a slow, minimal rise indicates a dry, tight system. With evacuation complete, the system is charged by weight and then fine-tuned using superheat and subcooling measurements that account for outdoor temperature and metering device type.

Airflow and static pressure are verified next. Blower speed taps or controller settings are adjusted to meet the target airflow per ton of cooling, and total external static pressure is measured to confirm the duct system and filter selection are not over-restrictive. Temperature split across the coil provides a quick health check, while electrical readings—voltage, amperage, and capacitor microfarads—confirm motors are within their operating ranges. Thermostat setup and control logic are configured for staging or modulation where applicable, and safety devices such as float switches and high-pressure cutouts are tested.

Commissioning ends with documentation and homeowner orientation. A complete report includes ambient conditions, refrigerant pressures, superheat, subcooling, airflow, static pressure, temperature split, and electrical readings. This record becomes the baseline for future maintenance and troubleshooting. The homeowner should receive a walkthrough on filter changes, thermostat scheduling, drain maintenance, and what to watch for season to season. Meticulous commissioning might feel like a quiet ceremony, but it is the moment when a collection of parts becomes a cohesive, efficient system.

– Critical commissioning data: superheat, subcooling, airflow, static pressure, temperature split, and electrical readings

– Protection details: correct breaker sizing, tight connections, drip-loop routing, and secured insulation

– Orientation points: filter access, thermostat features, drain safety switches, and maintenance intervals

Maintenance and Repair Diagnostics: Patterns, Readings, and Practical Fixes

Preventive maintenance keeps small issues from becoming breakdowns. Filters should be inspected regularly and replaced when loaded; many homes perform well with medium-efficiency pleated filters that balance filtration and airflow. Outdoor coils collect pollen and cottonwood; a gentle rinse from inside out, after power is shut off, restores heat transfer. Indoor coils benefit from periodic inspection and cleaning with coil-safe methods, especially in homes with pets or high dust. Condensate drains need a clear trap and line; flushing the drain and checking the safety switch reduces the chance of ceiling stains.

Diagnostics start with symptoms. Warm air during cooling, icing on the refrigerant line, unusual noises, frequent cycling, or water at the air handler each point toward distinct faults. A temperature split that is too low can flag low airflow or low refrigerant charge; a split that is too high can indicate restricted airflow or an overcharged condition. Superheat and subcooling reveal metering and charge health, while static pressure tells the truth about duct restriction. Electrical checks often catch failing parts before they quit outright: a start capacitor that tests outside its microfarad tolerance, a contactor with pitted points, or a blower drawing higher amperage than nameplate suggests wear.

Heating diagnostics follow similar logic. For heat pumps, defrost cycles should be verified in cold weather, and outdoor coils kept clean of leaves and ice. For combustion equipment, proper venting, flame stability, and heat exchanger integrity are critical safety checks performed under permit and code requirements. In all cases, recorded baselines from commissioning guide decisions. If today’s subcooling or static pressure differs sharply from last year’s reading under similar conditions, something has changed—often filter loading, duct blockage, or refrigerant loss.

When repairs are needed, start with the cause, not only the symptom. Replacing a failed blower motor without addressing high static pressure invites another failure. Clearing a clogged drain without fixing a missing trap allows the problem to return. Aim for durable solutions and document the fix along with before/after readings so the system’s story remains legible over time.

– Quick homeowner checks: filter condition, thermostat settings, breaker status, clear outdoor coil

– Clues worth noting: icing, odd smells, new noises, or water where it does not belong

– Data that speeds diagnosis: temperature split, static pressure, superheat/subcooling, and amperage

Repair vs. Replace: Budget, Timing, Sustainability — Conclusion

Every aging system eventually asks a hard question: repair or replace. A practical heuristic multiplies the estimated repair cost by system age; if that product approaches the price of a new, properly sized installation, a replacement merits consideration. Age is not the only factor. A younger system with chronic duct issues or persistent humidity problems may benefit more from a targeted duct upgrade than from new equipment. Conversely, a well-maintained older unit with rare, inexpensive faults can be worth keeping in service.

Costs vary by region, equipment type, and the scope of duct work. Whole-home replacements can range from several thousand dollars to five figures when extensive duct renovation is required. Operating costs are part of the equation as well; higher efficiency equipment and tighter ducts can trim utility bills, especially in climates with long cooling or heating seasons. Comfort features—quieter operation, steadier humidity, and improved filtration—carry value beyond raw energy savings, particularly for households sensitive to indoor air quality.

Environmental considerations are growing. Newer refrigerants generally target lower global warming potential compared to older blends, and responsible installation includes refrigerant recovery and leak testing. Right-sizing equipment and sealing ducts reduce energy use and emissions over the system’s life. During planning, ask for documentation that shows load calculations, duct sizing rationale, and commissioning checklists; these are your assurance that the investment is grounded in measured performance, not guesswork.

For homeowners and property managers, the most reliable path is to demand clarity. Request written diagnoses, before/after readings, and parts warranties for repairs. For replacements, ask for the load calculation summary, the selected airflow target, and the commissioning data you will keep on file. This paper trail makes future service faster and more accurate.

Conclusion: Treat HVAC as a system, not a box. Plan with data, install with precision, maintain with intention, and make replacement decisions with a full view of comfort, cost, and climate. That mindset turns complex equipment into dependable comfort, season after season.

– Decision checklist: total cost (installed), operating cost impact, documented sizing, duct condition, warranty terms, and commissioning plan

– Timing tip: schedule major work in shoulder seasons to reduce downtime and improve scheduling flexibility

– Long-view move: combine envelope upgrades with HVAC work to lock in smaller loads and steadier comfort