Enhancing Manufacturing Efficiency and Precision with State-of-the-Art Welding Technology

Introduction to Welding Machines

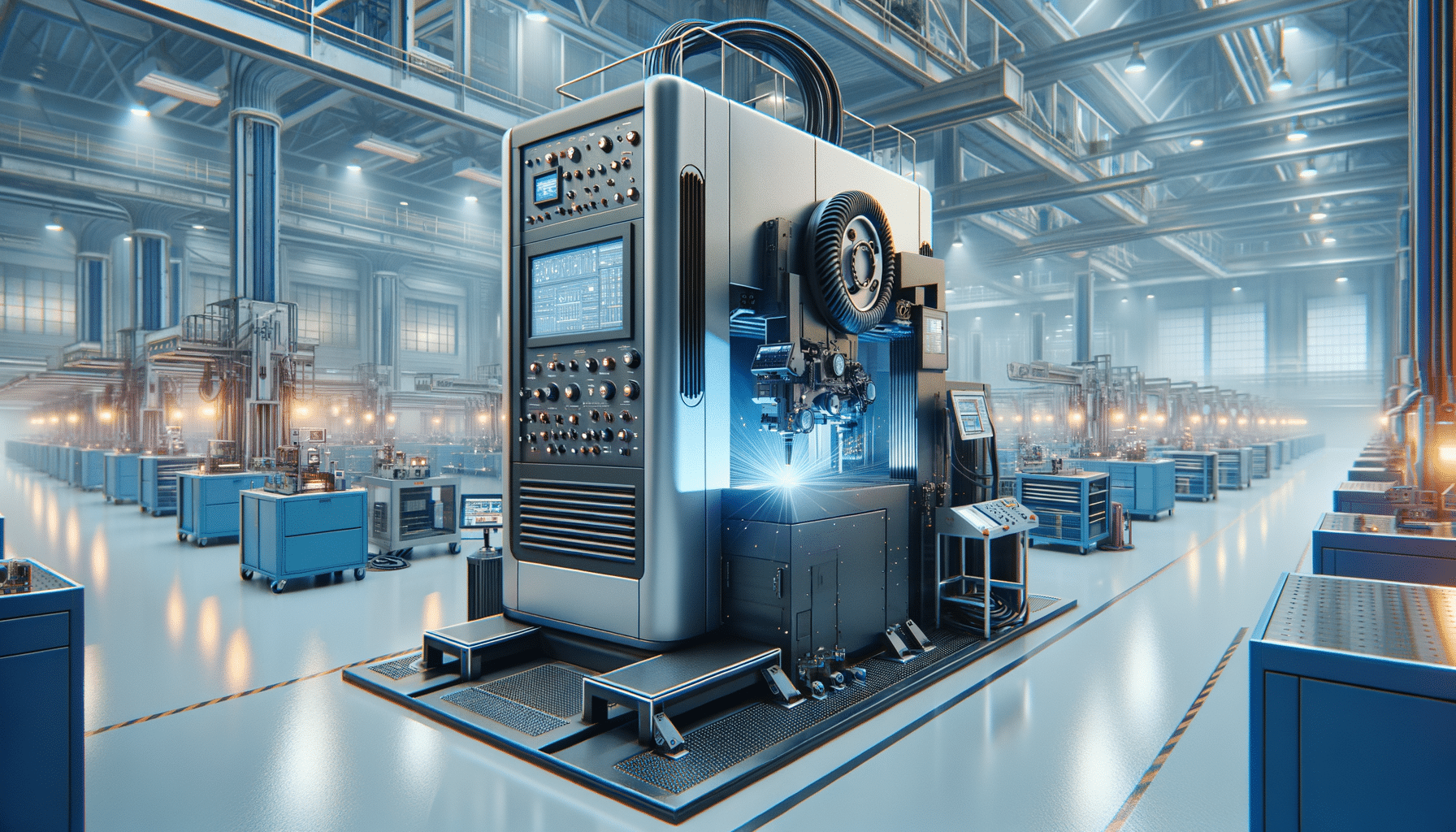

Welding machines are pivotal in the industrial and manufacturing sectors, acting as the backbone for fabricating and assembling metal structures. These machines have evolved significantly over the years, incorporating advanced technologies to enhance efficiency and precision. In today’s competitive market, leveraging state-of-the-art welding technology can provide a substantial edge, enabling businesses to streamline production processes, improve accuracy, and drive innovation.

Types of Welding Machines and Their Applications

The diversity in welding machines is vast, each type designed for specific applications and materials. Some of the most common welding machines include:

- MIG (Metal Inert Gas) Welding Machines: Known for their speed and ease of use, these machines are suitable for welding a variety of metals, including aluminum and steel.

- TIG (Tungsten Inert Gas) Welding Machines: Providing precision and control, TIG welders are ideal for thin materials and projects requiring high-quality welds.

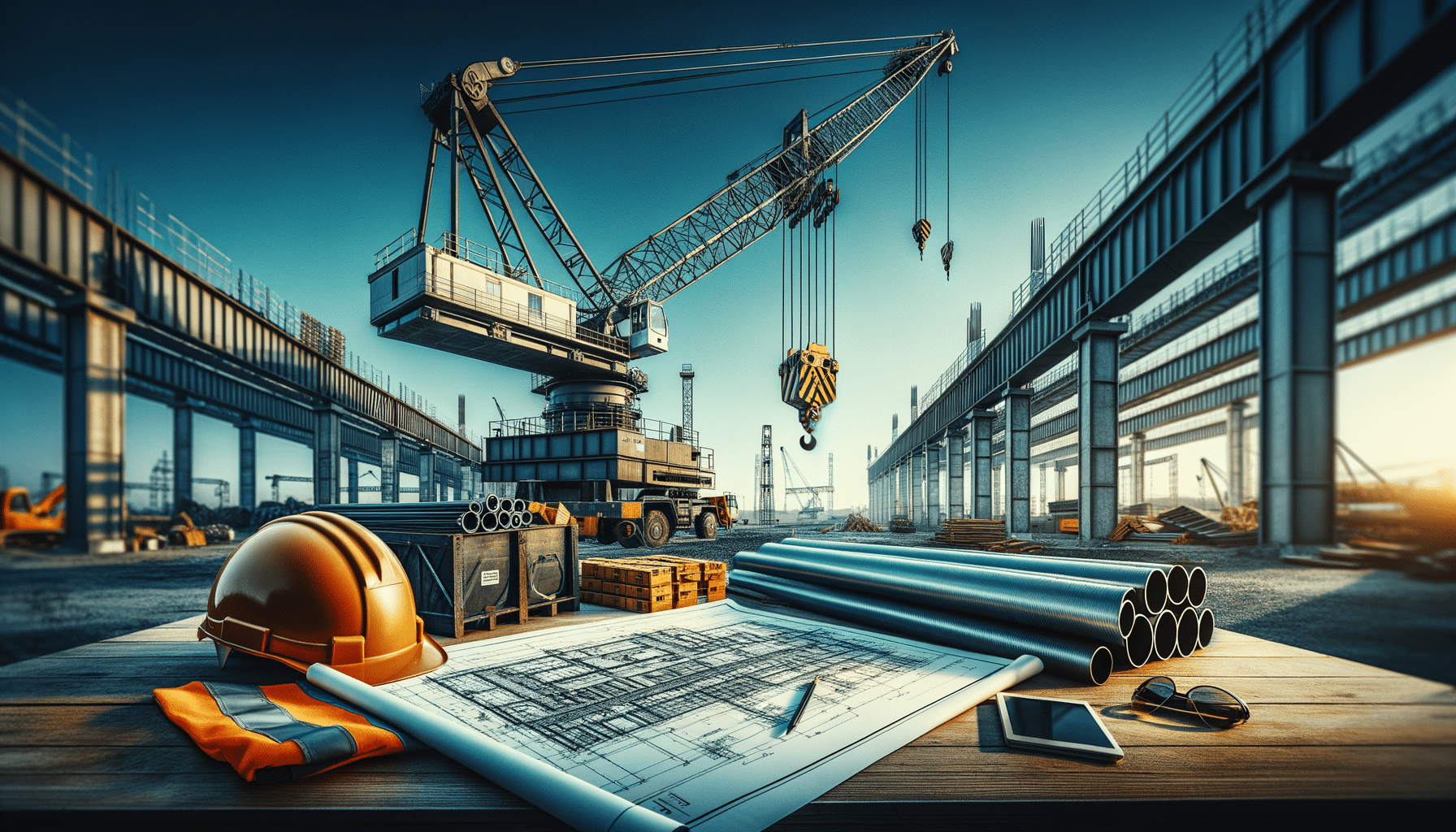

- Stick Welding Machines: Versatile and straightforward, these are often used in construction and repair work due to their ability to weld thicker materials.

- Plasma Arc Welding Machines: Known for their precision, these machines are used in aerospace and automotive industries where detailed work is crucial.

Each machine type has its unique advantages and is selected based on the specific requirements of the task, such as material type, thickness, and desired weld quality.

Advancements in Welding Technology

The integration of digital technology into welding machines has revolutionized the industry. Modern welding machines are equipped with features like automated controls, real-time monitoring, and data analytics, allowing for unprecedented precision and efficiency. These advancements include:

- Smart Welding Systems: Incorporating sensors and AI, these systems adjust parameters in real-time to optimize weld quality.

- Robotic Welding: Enhances productivity and consistency, particularly in high-volume production environments.

- Augmented Reality Welding: Provides training and skill development through immersive simulations, reducing the learning curve for new welders.

Such innovations not only improve the quality of welding but also ensure safety and reduce material wastage, contributing to cost savings and environmental sustainability.

Factors to Consider When Choosing a Welding Machine

Selecting the right welding machine involves considering several factors to ensure it meets the specific needs of your projects. Key considerations include:

- Material Type: Different machines are suited to different metals, so knowing the primary materials you’ll be working with is crucial.

- Power Requirements: Ensure the machine is compatible with your workshop’s power supply to avoid any operational issues.

- Portability: For on-site work, a lightweight and portable machine may be necessary.

- Budget: While advanced machines offer more features, it’s important to balance cost with the benefits they provide.

By evaluating these factors, businesses can make informed decisions that align with their production goals and financial constraints.

Conclusion: The Future of Welding Machines

The future of welding technology is poised for further transformation, with continued advancements in automation, artificial intelligence, and eco-friendly solutions. As industries strive for greater efficiency and sustainability, welding machines will play a critical role in shaping the manufacturing landscape. Embracing these technologies will not only enhance production capabilities but also foster innovation and competitiveness in the global market.